Tianjin Huali Thermal Insulation Building Material Co. Ltd. was founded in 1995 and put into production,is Located in 126 of Danjiang road, tanggu ocean science and technology park, hi-tech zone of Binhai, Tianjin. The company is mainly engaged in the production of thermal insulation material.

Introduction

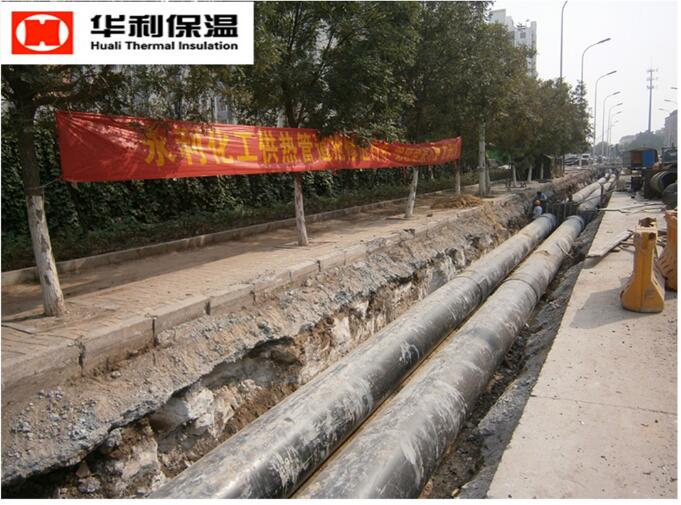

With the continuous improvement of the beautification of the urban environment, direct buried insulation pipe has been widely used in recent years.

With the continuous improvement of the beautification of the urban environment, direct buried insulation pipe has been widely used in recent years.

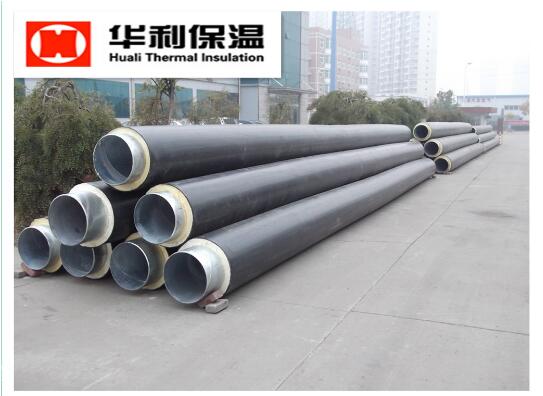

A polyurethane direct buried insulation pipe (steel pipe for conveying medium, high-density polyethylene jacket, and a rigid polyurethane foam filled with a steel pipe and an outer tube are tightly combined)

The utility model has the advantages of low thermal conductivity, strong water resistance and corrosion resistance, and good corrosion resistance and impact resistance at low temperature, and can directly buy frozen soil layer; the service life can be up to 30-50 years

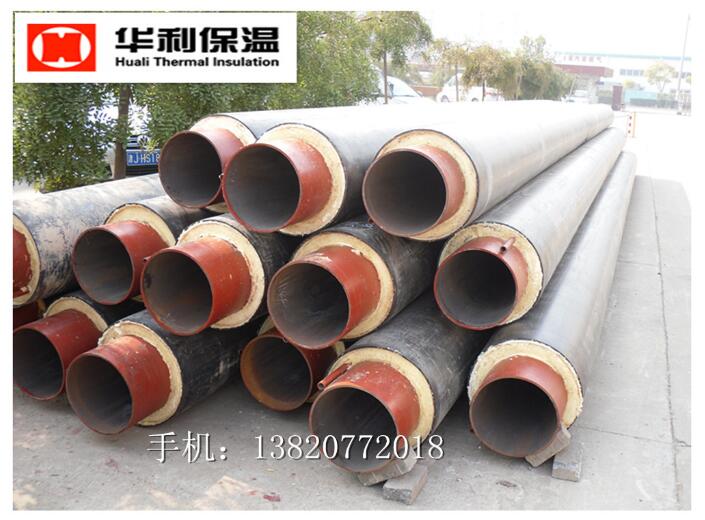

Two) steel sleeve steel directly buried insulation pipe (from inside to outside in order to work steel pipe, sliding support, insulation layer, reflective layer, air layer, protective layer, anti-corrosion layer

Because of direct buried insulation pipe is very complex system engineering, our company set up a professional technical team, with reference to foreign advanced technology, development and production of a pipeline -- the "steel" a new generation of thermal insulation, the product can be used for conveying steam below 500 DEG C or other heat medium. The technology of steel casing (steel sleeve steel) is a new technology of waterproof, leakage proof, anti permeability, pressure resistance and full sealing. The first problem is the protection of buried pipe pipe reliability strict waterproof, in addition to have good mechanical strength, high strength steel casing due to the use of welded connections, waterproof sealing performance reliability is very high, in addition, the high temperature performance and other external protective tube can match the. In the area with high groundwater level, in order to ensure that the groundwater does not affect the normal operation of the steam directly buried pipeline, the outer protective layer is preferably made of a strong and closed steel pipe shell. Implement one-stop service, design and develop safe and reliable implementation plan, production and construction.

The utility model has the following characteristics: 1. The long term safe operation reliability is high. The abrasion resistance of the colored material is not obvious, the sealing performance is good, the service life is more than 20 years, and the insulation effect is good.